PTFE Coated Medical Devices

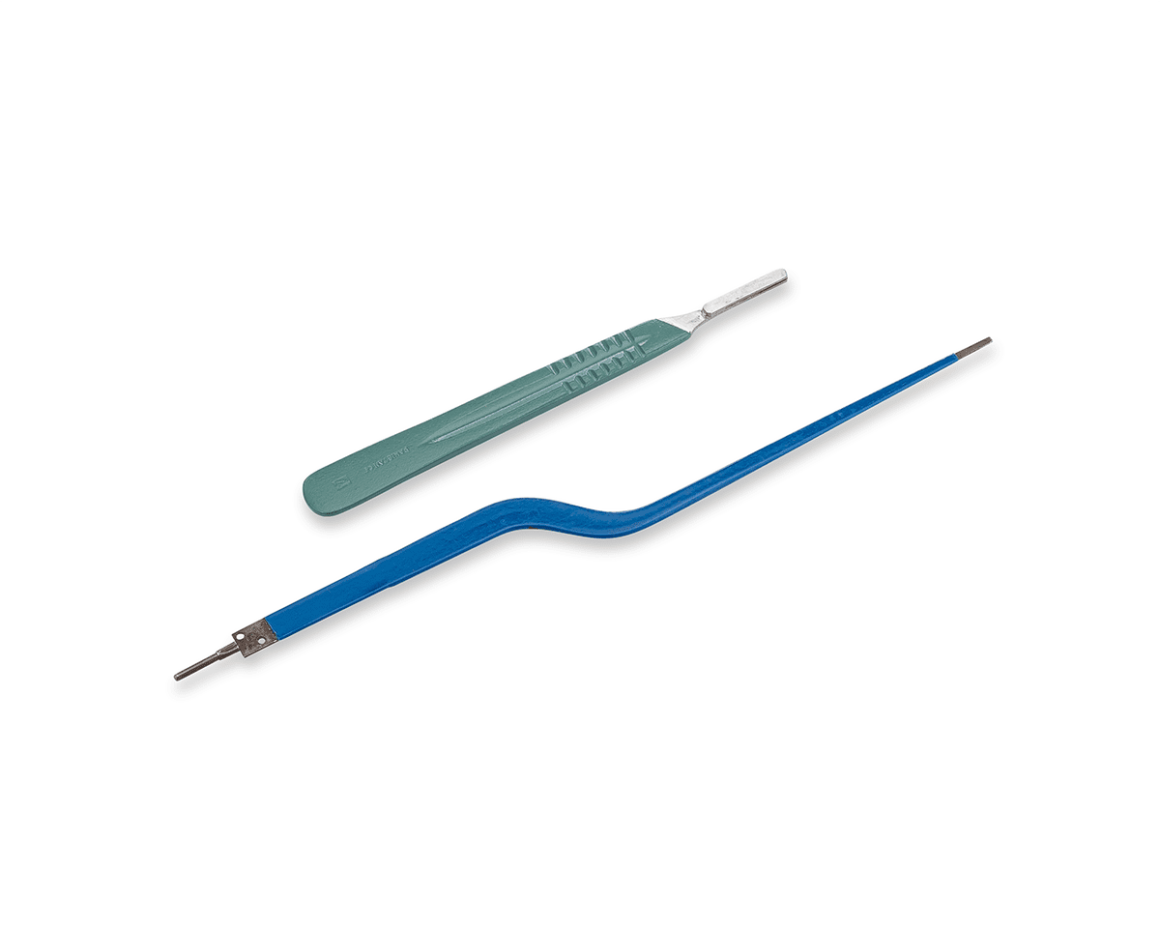

Many surgeries today are performed using PTFE coated medical device and surgical equipment which require non-stick, electrical insulation and other performance-related properties, such as safety, proper use and durability. In addition to the surgical environment, PTFE coatings are also common in medical and imaging labs. Just a few of these PTFE coated medical devices and applications include:

- Guidewires

- Mandrels

- Needles

- Electrosurgical blades

- Forceps

- Catheters

- Jaws

- Push/pull wires

A few of the different brands of medical grade coatings that provide these properties include:

- XylaMed® coatings

- Victrex™ PEEK coatings

- ETFE coatings

- Halar® ECTFE coatings

- Nylon coatings

- Teflon® coatings with risk analysis assessment

- And more

Medical PTFE Coating Formulations, Shapes & Sizes

Surface Solutions Group is a leader in applying PTFE medical device coatings on medical wire, with either aqueous-based or solvent-based no-PFOA formulations. We have available a number of grades, compounds and colors. We coat wire or mandrels in discreet lengths for medical devices. In-house tooling provides precise coating of semi-finished or finished guidewires in lengths from 2.54 cm to 635 cm lengths. We also coat guidewires in all stages of assembly, from the outer guidewire coil alone, without the taper mandrel and safety wire to a complete guidewire with the internal wires welded in place. Guidewire diameters of .012″, to .038″ in both round wire and flat wire and special sizes are coated daily.

Reel-to-reel coated or PTFE-coated wire is done automatically at SSG. With a special in-line pretreatment, SSG applies PTFE medical device coatings with optimal adhesion and superior uniformity. We can coat round sizes ranging from 0.005″ to 0.040″ in diameter plus coat Silver-plated Copper wire, too. Tubular devices are coated in both discreet lengths and continuous reel-to-reel lengths with our entire medical grade coatings and PTFE coatings.

After the coating application, Surface Solutions Group has the test procedures and instruments to verify 100% compliance of the applied coating specifications whether for prototypes, short run volume or high volume coating applications. SSG’s experience has made us one of the nation’s top specialty medical coating and PTFE coatings suppliers.

Our biocompatible coatings can be applied to disposable and reusable medical devices, instruments, and equipment. Having state-of-the-art automated electrostatic coating lines, we excel at high volume work and provide our customers with repeatability from part to part, assuring a uniform and micron-accurate coated guidewire or PTFE-coated guidewire.

Other PTFE Coatings Capabilities

VisiMark℠ technology provides contrasting color markings on PTFE coated medical devices for depth marking, placement guidance, on both solid and tubular devices. Special masking and VisiMark℠ are available on all guidewires and medical devices.

Surface Solutions Group can make any coating anti-microbial upon request.

FluoroMed® PTFE Coatings Specifications

- FluoroMed® Info Sheet

- FluoroMed® Coating List

- VisiMark® Info Sheet

- FluoroWire® Info Sheet

- FluoroMed® Anti-Microbial

- Engineering Evaluation Form

Contact us to discuss your project with a technical consultant.